Technology driven transitions

All transitions, especially new technology-driven transitions, that are global in its reach, result in big risks, even for strong incumbents in the industry impacted by the change. Most of the risks are unknown, before the technology achieves suitable level of maturity for larger scale usage. Some can be existential risks.

However, in most cases, these transitions result in significant opportunities to create and carve out extremely large, market opportunities. A sizeable subset of these transitions have an outsized impact in altering user/consumer behavior in profound ways.

While there is a large body of work about the disruptive impact of new technology on companies and industries impacted by the change, most of it is focused on higher level competitive strategy.

While this is an important line of investigation, it suffers from a major shortcoming.

Far too often companies fall short in the vital area of executing – making their strategy operational. And this problem plagues larger incumbents who get knocked off their perch by these transitions, and strong, mid-size competitors alike.

This paper is a study of one of the most critical transitions that is ongoing in the automotive industry – from polluting ICE cars to lower-carbon alternatives – which is yet in its early innings. It offers new ideas and approaches for operations management to prepare, plan and execute during these transitions effectively and efficiently.

The points surfaced here can be utilized by cross-functional operations leadership (product, operations – sales and supply ops, and operational finance) for any other technology-led, large-scale transitions that are emerging or ongoing in any physical products industry.

Automotive – A massive, bumpy transition, a looming imperative

The automotive industry is in the middle of a massive transition. This has resulted in big risks, and sky-high opportunities.

A massive, seemingly irreversible transition[1] is going on in the Automotive industry, starting with the large, well-capitalized economies– from legacy IC[2] Engines to Battery EV (or EV [3]) and other alternative energy auto options (hybrid, hydrogen, etc.), due to a confluence of many forces:

- Adverse impact of fossil fuels on humanity’s well-being on a large scale – pollution, air-quality, grave hazards to ecologies and humans caused by oil extraction companies and ICE autos, which is also a key ingredient causing extreme climate uncertainty. In 2020, the transportation sector alone accounted for about 20 percent of global greenhouse-gas emissions (source: McKinsey, McKinsey__Study-on_the-future-of-mobility).

- Resulting government regulations, along with controls, incentives and creative policies put in place by some of the largest global economy players and GHG[4] emitters – from EU to US to China, Australia, India, among many others.

- Availability of suitable technologies & materials – Although technologies are still far from optimal – for instance, EV battery materials resulting in more mining, potential future conflict between energy and food supply chain needs[5], greater dependence on energy from utilities, most of which are still dependent on carbon-intensive/dirty carbon sources, the supply-side of these materials have scaled up significantly over the last 5+ years, so has driving range and charging availability[6].

- Shift with bruising bumps in market demand[7] towards EV (and other low-carbon options), and away from the traditional ICE auto, despite higher prices of EVs/ alternatives versus ICE autos[8], near term demand slowdown notwithstanding.

- A major transformation underway among legacy ICE auto-makers as they slowly but surely wake up to the serious competitive, potentially existential threats posed by the electric transition, as a means to cut emissions, the technologically smarter pure-play EV companies making it, and the rising public awareness around climate impact of ICE autos.

Leading, pure-play EV makers, with their smarts in clean-sheet design in hardware, software, its integrated functioning, zero legacy operations baggage and consumer-friendly direct sales model, appear to have a sizeable lead over the legacy makers in engineering and manufacturing of EVs; as Jim Farley, CEO of Ford candidly admitted [9], not too long ago.

- Lower complexity Bill of Materials (BOM), a transformed product – Despite challenges in manufacturing[10] EVs at scale and attaining suitable margins, from a BOM standpoint, the EV is a simpler, and in key respects, a superior product too – beyond being fossil fuel-free. In addition, with the EV, the auto is going through a radical transformation – from a mechanicals-heavy to an electronics and software heavy product.

- Very Bumpy Transition guaranteed– As this paper was going to press (early January 2024) the drumbeat of downbeat and dismal news from the EV industry reached a high pitch. Demand for EVs appears to be stalling in the near term, down substantially from the rising trend that was emerging over the last 2-3 years (footnote#1). Legacy ICE automakers who had previously made bold commitments to allocate substantial resources to EV capacity, are reducing their EV commitments, often substantially (GM, Ford, etc.).

A sizeable number of legacy ICE automakers are instead cranking out more hybrids at the expense of EV’s to achieve their reduction goals.

The underlying EV technologies, and other ICE alternatives need to evolve and mature significantly and swiftly. Yet, it is clear to the informed consumer, especially those that can afford it, that they do not need a power station burning polluting fuel under the hood as they go from point A to B – the case with IC engines. For legacy ICE auto companies with significant direct emissions[11], transition to EVs and other low-carbon options, is a looming imperative.

In fact, this can be stated with a high degree of confidence[12] –for all ICE automakers, except very few, who started on their learning curve of EV operations a few years ago, the transition to a cleaner automotive technology, is an existential threat, as the inevitable shakeout takes place.

Planning & Preparing for the transition

So, how should the auto industry prepare itself for this transition – both the traditional ICE automakers and their younger EV rivals? Following are 2 key takeaways based on Zyom’s research and direct industry experiences[13] even if transitions were not of the same magnitude:

- Operationalize Long Range (5+ years) Planning – From operational standpoint, most long-range business planning cycles range from 12 to 24-month (hi-tech, electronics intensive industries).

In many industries, the range stretched out much more due to the choking of supply chains during the recent covid-19 pandemic, ongoing significant restructuring & retooling of supply chains, and altered goods flows due to strategic concerns over potential or actual lost capacity and resources

These stemmed primarily from the unpredictable conflicts impacting several regions – namely, Russia’s ongoing attacks on Ukraine (harness makers), China’s aggressive territorial postures towards Taiwan (semiconductor chips, rare earth/ other key EV raw materials), the Israel-Hamas war (OPEC majors’ region).

Our investigations indicate a longer time range planning process is required.

No, long-range planning cannot eliminate uncertainties caused by such unpredictable events. This leaves a big question –

how is this (long-range planning) different from Business Continuity Planning?

The key word here is ‘operationalize.’

Most long-range plans are basically of limited use, if not futile, since many of the key leaders who design and implement it – manufacturing and supply chain, sales, product-line management – realize, that planning for anything beyond 2 to 3 quarters, in rapidly changing, technology change intensive industries – is, at best a guestimate, in the worst case an output of little use – because plans beyond 2+ quarters are perishable, and it’s a fool’s errand to try and bring it back to life, or worse – modify those to utilize it in running operations.

Operationalize implies the ability of tying these long-range plans with plans in the tactical horizon (2-6 quarters out), ensuring these are not only tied with overall strategy, but also considers likely disruptions along various operating links, nodes, peoples, and evolving economics – macro and micro – across business cycles.

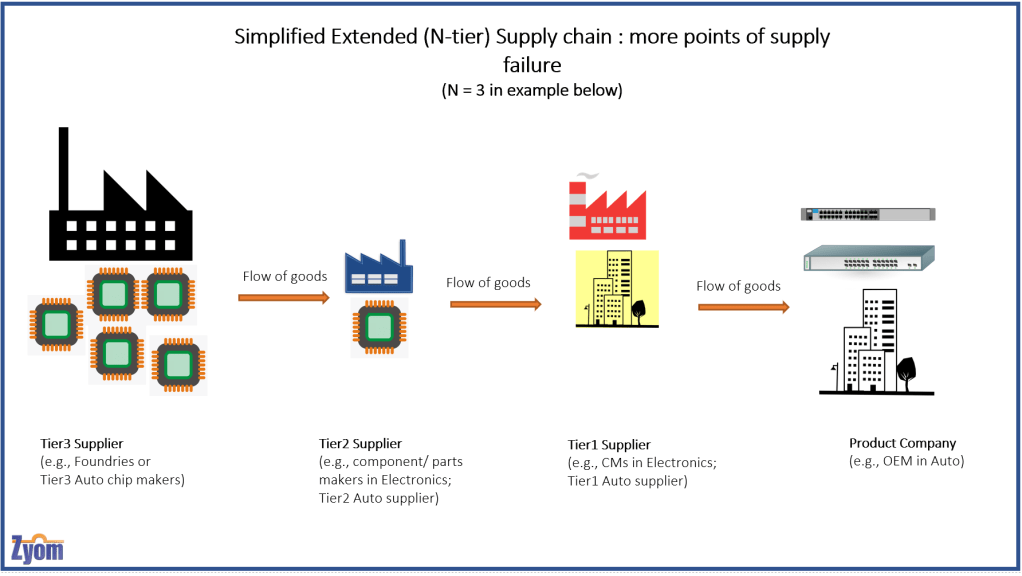

This is where a complete commitment to cross-functional knowledge, and capability sharing and collaborative planning is required across supply chain partners (product enterprise – auto OEMs, in this case, and their key suppliers – Tier1, some Tier2, and others upstream), and across functions within the auto OEMs (Product Line Managers, Sales and Manufacturing/ Supply Chain operations, and Cost/Value engineering).

Shrinking Window of opportunity – Legacy automakers, in the US and EU especially, need to make concerted efforts in operational long-range planning, since their “window of opportunity” to stay competitive maybe smaller than they think (case in point – Labor strife at the Big-Three[14] in the US resulting in a 25% labor cost increase[15], EU mandates for 100% EV production effective 2035).

Pure play EV manufacturers in the US, EU and Asia, except a few[16], may also have a rough road ahead, with a smaller and potentially shrinking “window of opportunity” versus legacy, ICE vehicle makers, due to the intrinsic capital-intensive nature of the industry (requires significant capital investment up front in plant and equipment), and extrinsic factors such as – intensifying competition from current EV leaders (Tesla world-wide, BYD of China), structural debt-intensive nature of recent macro-economic revivals (post covid-19 pandemic) – elevated inflation and higher interest rates, which has dampened EV demand based on the latest data (footnote#1). Large EV markets, such as China, are facing severe slowdown in demand.

In addition, unpredictable geo-political trade impasse (e.g., US versus China, EU v. China) also threatens to severely constrain critical raw-material inputs, and choke EV trade volumes.

Governments & the long view – A key contributor to long-range planning are governments and their productive engagement with new industries. In large, well-capitalized economies that are relatively free of state-control (the US, EU, Japan), private enterprises are driving most of the innovation, with some government support (example, loans to EV, battery and charging infrastructure makers). Automakers in the US, EU and mature economies that are currently leading EV adoption have benefited from this.

Chinese automakers’ selling price for EV is similar to the prices European automakers sell ICE cars for!

However, these automakers will find their hands tied as aggressive overseas competition heats up. Case in point – Chinese automakers’ selling price for EV is similar[17] to the prices European automakers sell ICE cars for!

A chunk of this anomaly can be attributed to the command-and-control structure of China’s (and similar) economies which enables national “champions.” However, governments and industry leaders in the US, EU and other free economies will be putting the economic success of their auto industries at grave risk without digging deeper.

What has benefited such an anomalous success in economies such as China, is a very long planning horizon[18] (10+ years). This has enabled companies in these economies to scale, often quite fast, capture a significant share of the nation’s market, and subsequently expand globally as well. Case in point – BYD, which started as a battery supplier in the late 1990s to mobile phone makers, and eventually expanded into making EVs. As of Q4, 2024, BYD is the largest EV automaker world-wide, having recently surpassed Tesla.

- Market Demand Signals – Big changes are afoot in this area, especially driven by the pure-play EV automakers. From a channel only centered (i.e., dealership only) demand generation and fulfillment model, to an OEM driven demand-gen and fulfillment model (via OEM showrooms, e-commerce website, etc.). This has profound implications for the OEM, and its supply chain, despite resistance to move away from the dealership model by large players[19].

The new model lends itself well to a BTO (build to order), or CTO (configure to order) model of managing manufacturing supply chains. This can be a significant game-changer for the auto industry. Like many other channel-intensive industries[20], auto industry has traditionally suffered from excessive supply clogging in downstream supply chain nodes – at dealers and distributors, who are the preferred, and often the only way, to fulfill end-customer demand.

The new model lends itself well to a BTO (build to order), or CTO (configure to order) model of managing manufacturing supply chains; this can be a significant game-changer for the auto industry

With the ability to switch to a more BTO or CTO centric model, and tightly aligning or cutting out the intermediary (dealership channel), demand generation and, end-to-end demand through supply planning, manufacturing execution and final customer order fulfillment is now the purview of the OEM. This will lead to much better visibility and better controls over finished goods stocks, long lead-time parts and sub-assemblies’ supply, faster feedback loops for corrective actions to be taken to right-size inventory, and get closer to the product mix that is selling in the market.

In addition, the virtuous cycle of rapid feedback on product options (options’ desired/ not desired/ hated) and rapid flow of product gaps/issues into product engineering, will provide a clearer line of sight on customer needs versus automakers’ aspirations.

With a clearer picture of demand, the industry can shift away from ‘Build to Forecast’ and all its ills (including, working capital tied up in dealer inventory) towards a primarily BTO/ CTO approach, and its virtuous cycle (lower inventory, better fulfillment, better understanding of customers’ product preferences, and perceptions).

Any residual capacity, if available at the end of a plan period (quarterly, every 6-months), can be used to build products that are in demand, or need fewer price-reduction type actions to move the inventory downstream from “stocking locations” to customers, or the capacity can be held back for vital upgrades and maintenance, or just planned downtime (theory of constraints and its virtues). In fact, even with rising demand, there may be a need for proactive residual capacity planning (à la inverse of “yield management” used in the airline industry).

even with rising demand, there may be a need for proactive residual capacity planning (à la inverse of “yield management” used in the airline industry)

A singular opportunity – Getting this transition right

History has some datapoints for us. At the turn of the last century (1880s to 1920s) the personal mobility industry in the US was going through one such major change (from horse drawn carriages to cars). From over 200 automakers, the field collapsed to eventually 3.

How did the last 15-20 dynamic automakers fall, leaving the field to the Big Three?

Better marketing, better manufacturing processes (Ford’s mass-production lines), better mix management (no options or very few), others? That maybe a topic for industrial historians to dive into. What is clear is that the Big Three were able to scale up their production effectively, meet the demand of a growing base of new consumers (sales, re-fueling and service), and do it all while keeping price points attractive, bringing increasing number of customers into the fold, and achieving and maintaining healthy profits.

Today (circa early 2024 and over the next 5-7 years), both legacy ICE automakers and pure-play EV makers face big challenges as they navigate this significant industry-wide transition.

Neither the incumbent ICE automakers, nor the disrupting EV makers have an unsurmountable advantage over the other, although select EV makers – Tesla and BYD – appear better placed.

This transition, like any transition of this magnitude, promises to be full of peril and near-term pain. However, there is an extremely outsized opportunity of industry-wide leadership for those that ‘survive’ this transition, achieve target unit economics to attain profitability, are able to sustain profitable operations, and the many unforeseen and un-plannable macro-economic and industry-wide disruptions that may surface, and throw the transition off course.

The grand prize is to be in the Big “x” (EV) makers (“x” being the unknown – will it be 3 in cars? 3 in pickups? 3 among truck makers, etc.). These handful will dominate the electrified (or alternate energy) vehicle future.

Automakers that effectively utilize these ideas, stay laser focused on mid and long-term profitability (2 to 10+ years), and ensure that in all major decisions they stay the course on ‘real sustainability,’ will ensure that they remain a force to reckon with for years, potentially decades to come. They will also play a vital role in the world’s safe transition towards net-zero and net positive environmental goals.

For the road ahead – A unique opportunity to gain an operational advantage

The transition and resulting changes expected in the automotive industry globally over the next 2-10 years will be complex and fraught with risks. This transition will be anything but linear (maybe, sizeable transition from ICE to hybrids versus EVs comes first, EVs later).

Both legacy ICE automakers and EV pure-plays – will need to become more cost competitive, while doing a delicate balancing act – simultaneously ramping up volumes of some products (EVs, hybrids, etc.) and throttling down on other legacy ICE products, while meeting a myriad of other critical needs (investors, regulators, competitors, public and others).

This is a time for companies to lean on specialists.

Zyom specializes in providing the most cost competitive operations management support system that has directly supported companies in industries going through transitions. How?

Zyom specializes in providing the most cost competitive operations management support system that has directly supported companies in industries going through transitions

By helping companies effectively utilize their cross functional operations teams, starting with manufacturing and supply chain operations, pinpointing specific areas of operational improvement, and implementing the needed capability in full. In many cases, this has resulted in a significant operating advantage – making companies among the most cost competitive in their industry, while balancing the needs of being demand responsive with progressively increasing volumes.

Industry leading results – briefly

Utilizing Zyom’s capabilities, a networking infrastructure provider in a new vibrant industry segment, achieved 10x the scale (volume shipped) within 4+ years, while achieving and staying profitable, and becoming an industry benchmark for cost-competitiveness in the process.

A Fortune 100 electronics industry leader radically redesigned their cross-functional processes utilizing Zyom to minimize inventory related costs, in response to a single product transition resulting from new technologies that had cost the company $10s[21] Million.

Ready to get into the Driver’s seat?

What makes the set of capabilities that Zyom equips its customers with unique are its innovations in these distinct areas:

- Closed loop operational planning and execution

- Product and Operations cost optimization

- Smart collaboration across functions and value networks

The capability set delivered is based on the specific transitions and changes the companies are planning for, or faced with, yet general purpose to evolve as needs evolve. Utilizing these, Automotive and other physical product companies can focus on specific, tailored capabilities to attain, maintain, or sustain profitable operations.

Ready to gain an operating advantage, or just get a copy of the Paper from which the above information is extracted, please reach out to the author via comments, or via https://www.zyom.com/contact.php .

Automotive companies, seeking profitability at scale, will gain a unique operating advantage, while navigating the ongoing transition – the twists and turns in the road ahead.

[1] As an early draft of paper went to press (Dec, 2023), news was pouring in about a potential slowdown in EV adoption in the US; click here for more: Why America’s Car Buyers Are Rethinking EVs, Bloomberg, Jan 2024

[2] IC = Internal combustion (as in IC Engine) or fuel-burning engines

[3] EV (or BEV) = Electric Vehicle (aka, Battery Electric Vehicles)

[4] GHG = greenhouse gases; the ones that trap heat causing climatic temperature rise over time

[5] Concerns about global phosphorus demand for batteries https://www.nature.com/articles/s43246-022-00236-4

[6] Although many geographies with limited EV charging infrastructure (see link in footnote #1 earlier)

[7] Some regions experiencing bigger shifts (e.g., California, USA, Norway/ other Nordic countries)

[8] Notwithstanding, near term slowdowns in the US (footnote #1 above)

[9] Jim Farley, CEO of Ford: https://www.cbinsights.com/research/tesla-disruption-legacy-automakers/

[10] Also servicing and maintenance costs are higher – many of these higher costs for customer are ‘unplanned’

[11] Emissions measured as Scope1, 2 and 3 per widely accepted industry guidelines from GHG Protocol

[12] Based on research & analysis of secondary sources (news, industry articles)

[13] Mobile phone industry’s transition – feature-phones to smart phones, others (Computing industry transitions)

[14] Big Three = Ford, GM, Stellantis

[15] Oct 30, 2023 UAW contracts with Big Three

https://www.cbsnews.com/news/uaw-strike-update-gm-tentative-agreement

https://www.cbsnews.com/news/uaw-strike-gm-stellantis-tentative-agreement

[16] A handful such as Tesla and China’s BYD have resources, developed channels & profitability to ride it out better

[17] Stellantis CEO Sees the Rise of Chinese Carmakers Fueling M&A, Feb 2024 Bloomberg/ Hyperdrive

[18] IEA Global EV; Outlook 2023 Catching up with climate ambitions ; https://www.npr.org/2023/07/22/1189580644/china-dominates-the-ev-battery-industry-can-the-rest-of-the-world-catch-up

[19] Toyota: Standing pat with dealers; Oct 2022 https://www.cnbc.com/2022/10/02/toyota-ceo-akio-toyoda-electric-vehicles-happy-dance.html

[20] Parallels with the channel-inventory intensive nature of Computing (PC) industry of 1990s are worth noting; Dell raced ahead utilizing a ‘Dell-direct’ model leaving larger incumbents – HP (Compaq) and IBM behind

[21] To find out value targeted and trigger event please reach out to Zyom https://www.zyom.com/contact.php